Michelo Alliance

We build

together.

Technology isn’t built alone. Michelo Robotics connects user problems with partner assets to grow a shared automation ecosystem. We collaborate with factories, hardware vendors, universities, startups, VCs, and integrators to accelerate real-world robotics.

Co-Build the Intelligence

The core of Michelo AI is not code or hardware alone, but algorithms that observe and learn from human behavior.

That’s why we co-develop with field experts in models like these:

Industry

Academia Model

2D/3D vision, surface-treatment simulation, user behavior modeling (e.g., sanding algorithms with University A’s ME Dept.)

Robot HW Integrated Development

Modular co-dev with robot OEMs and equipment vendors (e.g., customized interfaces with leading robot H/W firms)

Testbed

Agreements

Site-specific demo lines installed

→ iterate with live feedback

Customer Story

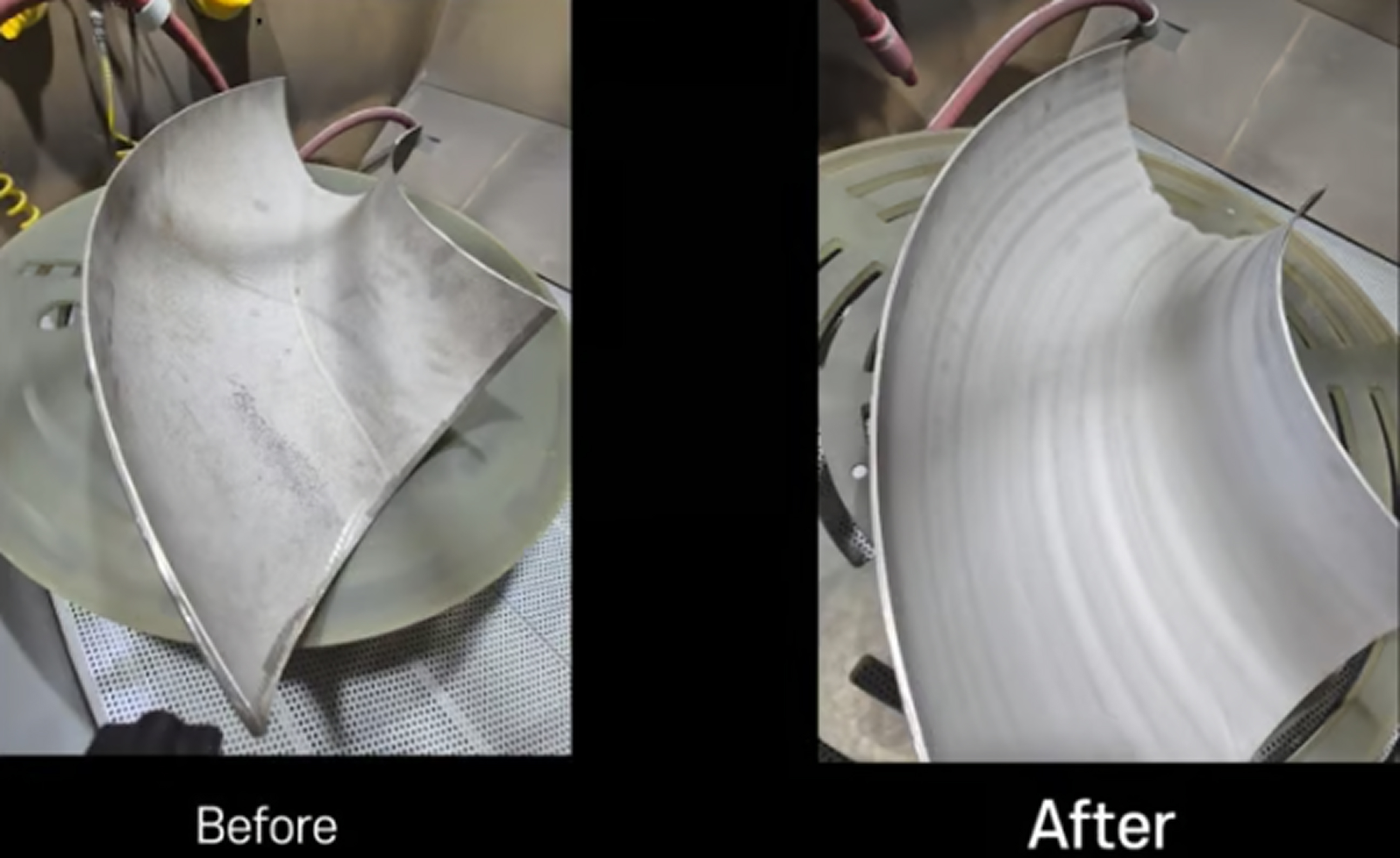

Setting a new benchmark for nuclear decontamination

Automated decontamination with Michelo AI—pursuing zero radiation exposure

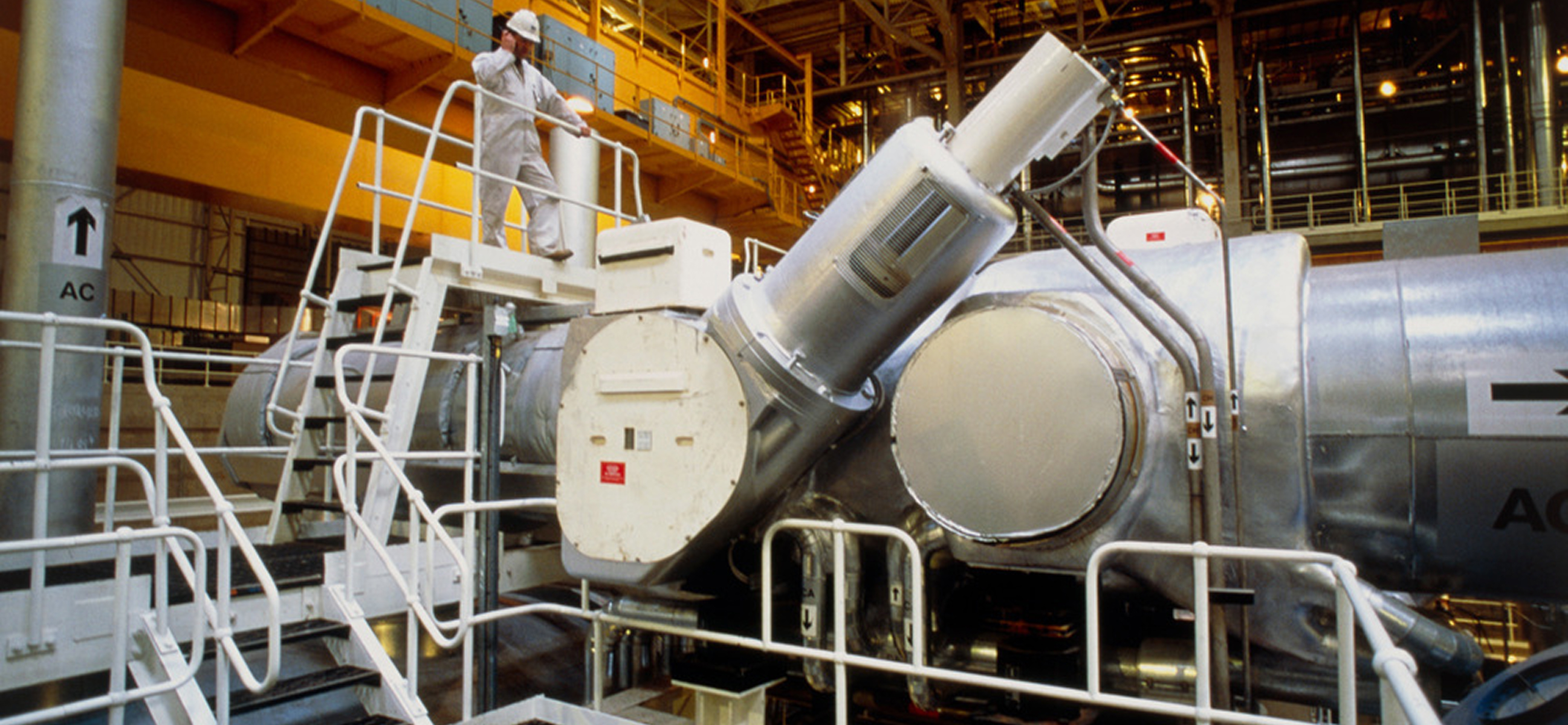

Nuclear decommissioning demands the same rigor and safety as construction. Of 209 shutdown reactors worldwide, only 21 are fully decommissioned; a KRW 500T market is emerging. One of the toughest, riskiest steps is abrasive decontamination of radioactive metal waste. Historically, experts abraded complex curves by hand—exposed to radiation, with variable quality and long cycles.

Client

SUSAN Industry

SUSAN Industry, a plant-based steel structures leader, is expanding into decommissioning and internalizing key tech. Our collaboration began with automating “very low-level” radioactive metal decontamination an ambitious first step.

Michelo AI

Deployment Overview

Awarded Project

For nuclear metal waste,

automating repetitive

abrasive decontamination

Adopted Technology

Imitation-learning abrasive

control built on Michelo AI

Prior Method

Manual, high-risk, and variable

Key Modules

Michelo Motion (Learns demonstrated expert motions)

Michelo Vision

(Detects geometry and contaminated areas)

Michelo Autopath (Generates paths; optimizes pressure/speed)

Outcomes

Metric

Before

Decontamination quality variation

±30%

Manual ratio

100%

Radiation exposure risk

high

Cycle time

avg. 150 min

Secondary waste

irregular

After

Within ± (target range)

0% (fully automated)

Robot only operations

~85 min (−43%)

Minimized (precision abrasion)

“Very low-level decontamination requires both precision and safety.

Portal301’s technology learns expert handcraft,

so robots abrade smoothly like humans and remove only what’s needed.”

“The pilot results were impressive,

and we are now deploying the commercial solution together.”

Ho-Geun Ryu, Principal Researcher,

SUSAN Industry Technology Lab

Opening the gate to the global decommissioning market

Through this project, Michelo Robotics completed Korea’s first field validation

of robotized abrasive decontamination and is entering the market.

Now Michelo AI

goes beyond repetitive automation

reducing radiation risk, improving quality,

and establishing the technical base for global-scale decommissioning.

Investment · Co-Branding · Global Partnerships

We actively pursue strategic partnerships for the industries of tomorrow.

Link to early-stage investors

Co-design PoCs

(VCs → customer rollout + tech validation)

With partners

Co-branding campaigns

(e.g., joint expos/seminars with automation

HW vendors)

Global

Expansion partnerships

APAC/US/EU distributor collaborations

(joint trademarks and installation agreements)

With leading organizations, Michelo Robotics is

co-designing

the intelligent robotics ecosystem.