Bringing Human Sense to

Robot Intelligence

Technology that remembers human sense

that’s Michelo AI.

We are not building robots that merely move like humans we are creating intelligence that learns the way humans do.

Michelo Robotics is designed so that AI can directly observe and learn the “skills” of the industrial field. Technology may calculate, but we embed

human senses within it.

Struggling with high-mix production?

With frequent changeovers—two to three times per week in high-mix, low-volume settings

you need operator-driven robotic automation that’s simple enough for the shop floor.

High product variety means

frequent changeovers

up to twice per day, typically two to three times a week.

Complex robot programming

keeps operators from running the system,

and outside experts cost ~ KRW 1M per day.

High system cost

blocks adoption

typical line unit cost at a U.S. vendor: KRW 3–5B.

To solve this, Michelo Robotics delivers

operator first,

auto-manual hybrid automation

tailored for real production floors.

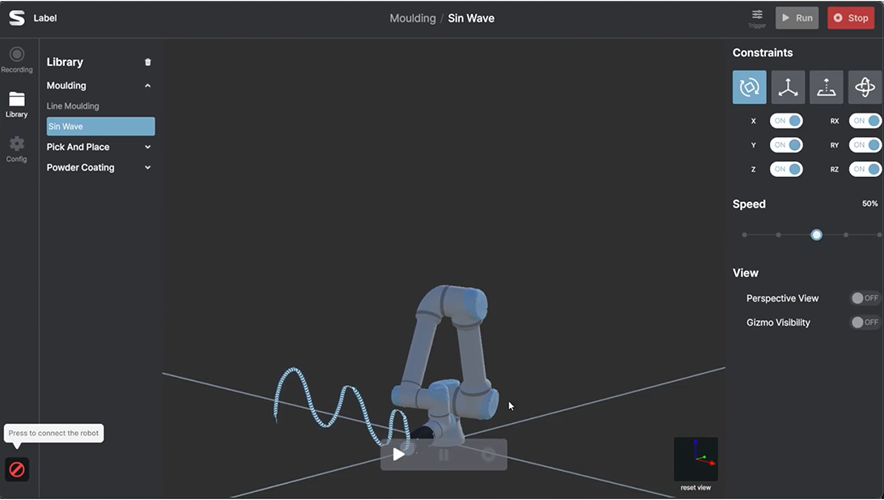

01

No-code operating UI

An intuitive interface lets operators configure robots with zero specialized training.

02

Auto changeover templates

Save and recall task recipes to switch products in seconds.

03

Optimized for collaborative robots

Flexible motions and safety designed for human-robot collaboration.

04

Adaptive smart teaching

Robots learn paths from a single operator demonstration.

05

Automatic path generation

AI perceives part geometry and computes optimal angles and trajectories automatically.

Or is automating manual processes your bottleneck?

01

Robot systems are too hard.

Endless settings and complex code keep front-line teams out.

02

Adaptive smart teaching

Even “simple” block coding is a real barrier on the shop floor.

03

The operator’s “craft feel” doesn’t transfer to robots.

Tacit skill and judgment don’t fit rigid automation logic.

04

Calling experts is too expensive.

Recurring vendor call-outs drain time and budget.

Here’s how Michelo Robotics fixes it all.

Our

Human-in-the-Loop automation

reinterprets advanced robotics for real-world usability.

01

No-code interface for non-experts

Operate robots like a mobile app—simple, visual, accessible.

02

Demonstration-based teaching

Show it once; the robot repeats. Tacit know-how becomes repeatable robotic motion.

03

Hybrid human-robot collaboration

Robots handle repetition; people handle nuance for throughput and quality.

04

Zero expert dependency, lower OpEx

Operators do setup and changeovers themselves faster and at lower cost.

Then

the one platform to solve it all.

AI-native automation for manual processes.

Michelo tackles the shop floor’s real problems.

Challenge 01

Quality varies

by operator.

Variability drives claims and yield loss.

Challenge 02

Setup is

too complex.

Changeovers require experts every time.

Challenge 03

Many tasks are

repetitive

and hazardous.

They expose workers to injuries and risk.

Challenge 04

Craft knowledge

isn’t transferred.

Tacit skills fade without capture.

Solution 01

AI stabilizes quality.

It learns from masters and repeats consistently.

Solution 02

Auto-generate paths in a few clicks.

No code operators complete setup quickly.

Solution 03

Robots take on repetitive and risky work.

Operators supervise for safer, steadier throughput.

Solution 04

Capture skill in a single demo.

Demonstrate once; repeat on demand.

Manufacturing, re-architected by

It’s not incremental it reshapes your production model.

Up to 70% reduction in labor cost

Run former 3–4-person cells with a single supervisor.

2~3× increase in output

Scale from 500 units/day to 1,500+/day.

Uniform quality with minimal loss

Precision without human variability keeps quality consistent

and cuts defects dramatically.

Automation now

belongs to operators.

We tailor automation to people easy for anyone, so everyone can execute like a master.

Stop overcomplicating automation—start true smart manufacturing with

Michelo AI.

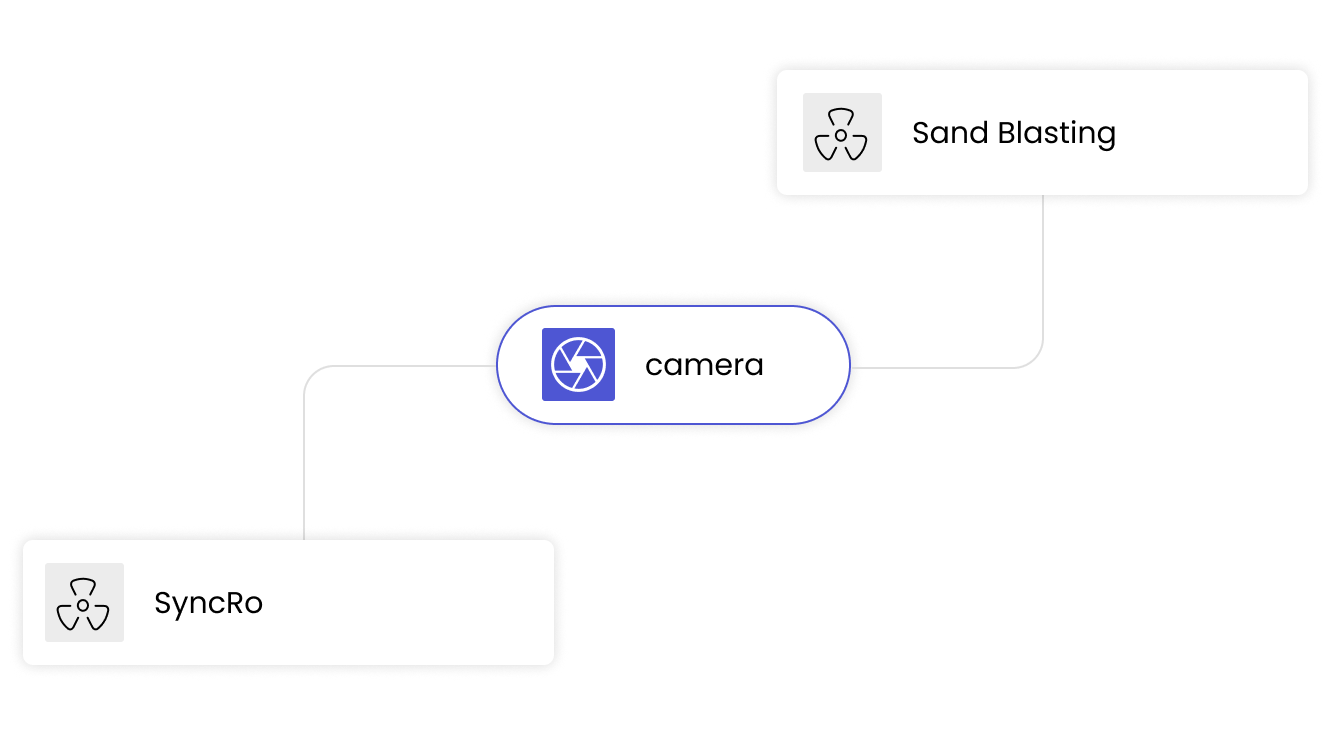

By analyzing the surface,

robots automatically complete

surface-treatment tasks.

By imitating human motion,

we automate surface treatment.

Use case) Powder & liquid paint spraying

(Powder Coating, Paint Spraying)

With onboard cameras, robots execute

surface-treatment tasks autonomously.

Use case) Nuclear waste decontamination

(Sand Blasting)

From Portal 301

We are reborn as

Michelo Robotics

We chose a new name to go beyond robotics to build intelligence for people.

Michelois our pledge to craft precise technology like art—and to remember human sense.

Technology shouldn’t replace people; it should coexist with and extend them that’s our path.

We’ve retired the name “Syncro”

and unified the product brand as

Michelo AI

We’ve moved beyond path imitation Michelo AI

understands intent and context behind human motion.

On site, show the task once,

vision learns it and the robot executes.

Michelo AI remembers, learns, and decides.

It’s not rote repetition it resembles human craftsmanship.

Hand motion

Tool angle

Reason for pauses

Recurring mistakes

Michelo AI

is built from four modules

an integrated intelligent robotics platform.

Michelo Motion

Generates paths by learning human hand motions

Michelo Vision

Perceives geometry/pose/lighting and compensates

Michelo Autopath

Auto-generates and refines optimal paths

Michelo Toolkit

No-code interface anyone can use

When operators demonstrate on site,

vision learns and the robot performs.

Michelo AI remembers, learns, and makes decisions.

Not mechanical repeatability—human-like mastery.

All robot manufacturers supported.

Start with